Factory Tour

Global Experience

Manufacturing for famous medical product companies in Germany, Netherlands, Japan and S.E. Asia.

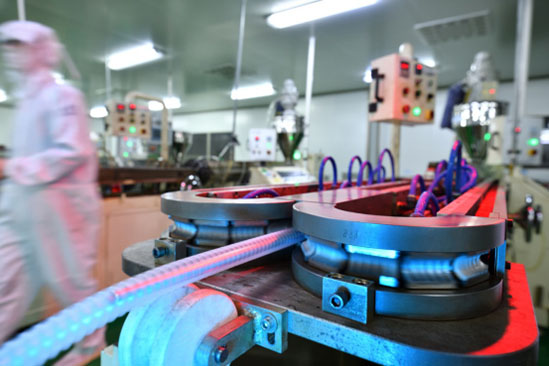

Qualified Manufacturing Environment

Class 10,000 and 100,000 clean rooms. Installed with equipments for injection, blow molding, extrusion and product assembling.

Engineering Team

Well-educated and well-trained staff, guiding all aspects of the whole process from design to mass production.

High Quality

ISO9001, ISO13485, “CE” certifications, “FDA” and “CFDA” registered, compliance with “GMP” requirements.

Reliability

Sophisticated project management and ERP(SAP) system to ensure timely delivery and accurate budgeting.

Full-service solutions and dedicated support

● Product design and development ● Quality control and regulatory compliance ● Manufacturing and fabrication ● Packaging and sterilization ● Technical support

● Order fulfillment & flexible distribution options ● Project management

Core Competencies

Class 100,000 clean room environment

● Plastic Extrusion & Corrugation

● Blow Molding

● Clean Room Assembling/Testing

● Ultrasonic, High Frequency & Heat Welding

● Semi-automated Assembling

● Clean Room Laser Cutting

● Vacuum Form Packaging

● Clean Room Pad & Silk Screen Printing

● Packaging,Labeling,Bar-Coding

● Medical Electronic Assembly

Other Production Process

● Die-Cutting ● Injection Mold Construction Shop ● On-Site EO Sterilization